DECIPHERING CRAZING ON SPA AND BATH SURFACES

Crazing, a term frequently mentioned in spa care and maintenance, refers to the fine web of micro-cracks that can emerge on surfaces subjected to stress. While typically associated with spas, this phenomenon can also affect other bath products like bathtubs, showers, and sinks constructed from FRP (fiberglass reinforced polyester) or cultured marble.

These intricate crazes usually originate in areas under high tension—around scratches, imperfections, or any molecular inconsistencies. They are most commonly a response to tensile stress, with the micro-cracks spreading perpendicularly to the direction of the stress. Notably, thermal stresses from temperature fluctuations can also lead to crazing, especially in gelcoat products where such thermal cycling is prevalent.

It’s often the combination of mechanical and thermal stresses that culminates in crazing, particularly in brittle, amorphous polymers like polystyrene (PS), acrylic (PMMA), and polycarbonate (PC). The acrylic used in spas is engineered for durability; however, extreme conditions can lead to its failure.

Research by acrylic manufacturers has pinpointed two simultaneous conditions essential for crazing to occur: substantial stress within the acrylic and exposure to a potent stress-cracking agent. Isolated, these factors are insufficient to cause crazing. The minute micro-cracks are typically the result of the stress forcing apart the dense polymer chains, allowing solvent molecules to infiltrate and act as a lubricant, facilitating further separation and crack formation. The extent of crazing is influenced by the level of stress and the harshness of environmental factors, such as chemical solvents.

Residual styrene, a byproduct of incomplete polymerization in polyester resin systems, is a recognized catalyst for crazing due to its potent stress-cracking capabilities. However, definitive identification of crazing causes in specific instances necessitates chemical analysis.

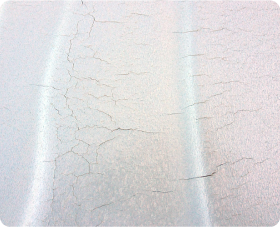

Illustrations of typical crazing on an acrylic spa surface, when magnified, reveal an intricate network of these tiny fractures. To mitigate the risk of crazing, especially in outdoor spas, the use of a spa cover is strongly advised.

GELCOAT CRAZING: UNDERSTANDING AND REPAIRING SURFACE ALLIGATORING

In the specialized domain of gelcoat and FRP (fiberglass reinforced plastic) products, a phenomenon known as crazing—or colloquially, “alligatoring” — presents itself asa complex web of fine surface cracks. This condition arises when a thick layer of gelcoat, which is less prone to flexing, gradually loses its elasticity and becomes brittle. Such brittleness is often accelerated by the frequent temperature shifts that cause the material to expand and contract, putting stress on the gelcoat’s integrity.

Furthermore, exposure to harsh chemicals can compromise the gelcoat’s resin, contributing to the weakening of its molecular bonds. As these stresses accumulate, they can cause the resinmolecules to pull apart, resulting in the formation of small fissures on the surface.

It is essential to note that crazing is typically confined to the gelcoat layer, sparing the underlying FRP structure from damage. This localization to the coating significantly simplifies the repair process, making it a less complex issue to address compared to structural concerns. With proper treatment and refinishing techniques, surfaces afflicted with gelcoat crazing can be restored to their original luster and strength, ensuring prolonged durability and aesthetic appeal.