|

Variations in pigments from batch-to-batch as well as differences in manufacturing conditions in the acrylic sheet and the thermoforming process cause small differences in color in a specific final products and even location on the product surface. For example, acrylic sheet is heated and stretched into the shape of the final product. It is reinforced with fiber glass, which is colored. The sheet becomes thinner in the bottom of a bathtub, and becomes translucent. The “shadow” created by the color of the reinforcement can affect the color observed on the tub surface, since the sheet is normally translucent. Also, as in carpet manufacturing, the sheet production process creates color differences. These differences can often be detected visually. Therefore, in order to get the “best’ color match, toning of the base coat(s) used for the repair may be desirable. Multi-Tech Products offers toners and toner kits for this purpose. Success requires practice and developing the skills to recognize color shades and the requirements for achieving the right color shift. The simplest adjustment is lightening or darkening by using the white or black toner supplied with standard repair kits. |

|

Knowing the right toner that makes up a color is a good start and useful information. Our guide below gives you the basic colors within a color range (or family of colors). The guide is also available in PDF format to downloand or print by Clicking Here. An important factor is seeing what the surface color needs that is being matched, and adding the missing color to the mixture. This is done by applying the attempted matched mixture to the surface, comparing the visual shades, and adjusting with toners. This is a process and will take several attempts to get an acceptable match. Please Note: To make color matching simple, most common bath ware colors can be matched using a white base, black (brown black), yellow oxide, and red oxide toners. These three toners are an essential part of any surface repair kit and essential for White, Biscuit, Almond-Bone, Grey and Rose color matching and adjustments. This rule and techniques apply to most other surfaces, coatings and industries as well. We carry three different kits based on the skill and degree of color matching levels.

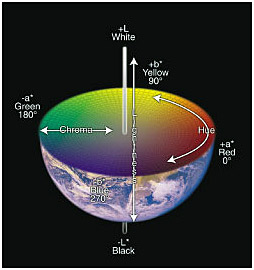

Surprisingly to many, all colors can be defined numerically. Color technologists have created the science which uses L “a” and “b” values for the four primary colors and white or black. L is a number that indicates the relative amount of white or black and is the height axis of a three-dimensional graph. The “a” value indicates the ratio of red (a+) and green (a-). The “b” value represents the ratio of blue (b-) and yellow (b+). These three numbers will locate a specific color in the graph space as shown below. Color values are measured using special instruments, colorimeters or spectrophotometers. Colorimeters were the pioneers of color measuring instruments. Colorimeters view a sample through at least three filters, measuring the quantity of light reflected from the sample as it passes through each of the filters. The filters were originally designed to mimic the response of the red, blue and green cones of the eye as closely as possible. This, at first glance, seems to have merit, since it attempted to imitate the eye of the standard observer. However, an important deficiency of colorimeters is they cannot separate the pure color from the appearance of an object. Additionally, a colorimeter is unable to detect if an object’s color will appear differently under different light sources. Therefore, colorimeters have limited capability when compared with current technology.

|

| The following table provides tips and guidelines for adjusting base colors using black, yellow oxide, chrome yellow, red, red oxide, blue, green, raspberry, orange, and brown toners supplied by Multi-Tech Products. Refer to the current catalog for a complete listing of available toners. |

| SOLID COLOR ADJUSTMENT GUIDELINES |

|

Start color

From base

To darken, use

To adjust color, use

To adjust hue, use

|

|

White

White

Black

Yellow Oxide

|

|

Almond/Bone/Biscuit

White

Black or Green

Yellow Oxide

Red Oxide

|

|

Light Gray

White

Black

Yellow Oxide

Red Oxide

|

|

Pink/Rose

White

Black

Red Oxide or

Raspberry Yellow Oxide

|

|

Light Green

White

Black

Green

Green or

Yellow Oxide |

|

Dark Green

Green

Black

Blue

Red or

Yellow Oxide |

|

Light Blue

White

Black

Blue

Green or

Yellow Oxide |

|

Dark Blue

Blue

Black

Red Oxide or

Raspberry Yellow Oxide

|

|

Dark Brown

Brown

Black or Green

Red Oxide

Yellow Oxide

|

|

Dark Red

Red

Black

Red

Chrome Yellow

|

|

Other Red Tones

Red Oxide

Black

Red

Chrome Yellow or

Yellow Oxide |

|

Mauve/Raspberry

Red

Black

Raspberry

Chrome Yellow

|

|

Yellow/Harvest Gold

Yellow Oxide

Green

Chrome Yellow

Red Oxide

|

|

Yellow/Jersey Cream

White

Black

Yellow Oxide or

Chrome Yellow Red Oxide

|

|

Black

Black

Black

Raspberry or

Yellow Oxide |

|

| Top of page |

Categories

- Bath & Shower

- Spa and Hot Tub

- Quick Glaze System

- MMA System

- Repair Filler Putty

- Surface Prep

- Texturing & Safety Additive

- Acrylic & Plastics Adhesives

- K2000 Products

- Acrylic & Gelcoat DIY Pastes

- Gelcoat Products

- Resins & Pastes

- Resin Additives

- Resin Thickeners

- Fiberglass

- Foam Support

- FRL Refinishing System

- Solvents & Strippers

- Laminating Tools & Supplies

- Plastic Jars & Bottles

- Glass Jars & Bottles

- Mixing Cups & Buckets

- Metal Cans

- Airbrushes & Touch-up

- Spraying Accessories

- Safety & Personal Protection

- Buffing & Polishing

- Sandpaper & Abrasives

- Repair Accessories & Tools

- Electric Tools

- DIY Products

- Instructional Videos

Quick Links

- Technical Info

- Applications

- About Us