Plastic bath and spa products are of a composite structure consisting of a surface layer(s) and a reinforcement layer. De-lamination is the separation of these layers at their interface. This occurs since manufacturing conditions led to low or non-existent chemical adhesion of the two layers. In some cases a delamination or separation of the support or reinforcement wood, core or other materials can occur causing hollow or voided areas typically on the floor area of a composite bath tub or shower unit. This can occur in the footwell of spas, and on decks and/or panels or FRP boats and related composite products. This type of separation is not to be confused with fluid filled blisters. Delaminations will occur without the thick fluid associated with osmotic blisters. Water may be present associated to the usage environment.

How to Repair Acrylic Surface Delamination:

Theoretically acrylic can be glued or reattached using a polyester resin or acrylic adhesive. The question would be, can the acrylic be reattached to lay smooth with good adhesion?

read instructions »

read instructions »

How to Repair Support or Structural Delamination:

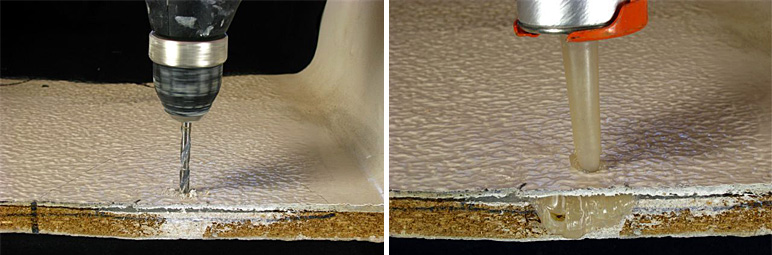

Unit was cut for Side Illustration

Inject Resin or Resin Paste

A hole(s) will be drilled through the interface to the delamination cavity. A high quality resin or paste will be injected into the cavity to fill the void and adhere the two surfaces together. read instructions »

The goal is to fix the delamination issue with an injection process followed by a cosmetic repair. In the case that the structure still seems weak or movement is present. It may be necessary to inject dense foam to stop movement or build strength with reinforcement or an overlay application. To optimize time and material used it is best to make this judgement at the start of the repair job.